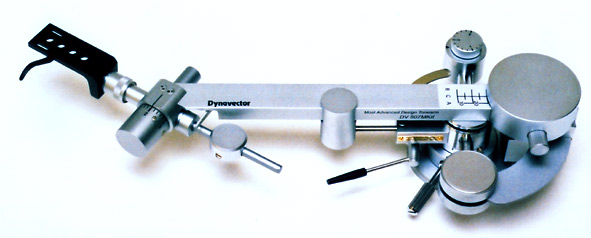

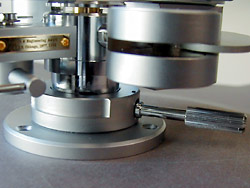

Dynavector DV 507 Mk2

Dynavector DV 507 Mk2

$5,450.00

The Long-Awaited Debut of the DV507MKII

The new MKII version of the Dynavector DV 507 tonearm

has made its long-awaited debut, building on the strengths of the

original DV 507 which has enjoyed the highest reputation among

audiophiles world-wide since its appearance in 1984.

As it is a bi-axis inertia controlled tonearm the

DV 507, no matter the type of cartridge can trace the music signal

grooves cut in the recording with extreme accuracy. The DV 507

also provides superb trackability on warped recordings. Resolution

and musical detailing are quite remarkable.

![]()

| 1 | Advantages of Bi-Axis Inertia Controlled Dynamic Balance Type Tonearm |

A tone arm is required to operate

in two important ways so as to ensure that the cartridge can

reproduce faithfully the signal from the record groove.

First, there is the need to support the cartridge

so that the transfer of the cantilever motion accurately mirrors

the audio signal.

Secondly, it must maintain an excellent tracking

ability for warped records since few records are perfectly flat.

These requirements can conflict with each other.

However, the bi-axis tonearm provides an effective solution to

the problem.

| 2 | Main Features |

-Electro Magnetic Damping System for accurate tracking

|

To make the DV 507 MKII compatible with a wide variety of The DV507MKII has important sonic improvements as well as being

"Bi-axis inertia separation" may The DV507 bi-axis tone arm has a large inertia It is well known that a cartridge generates In these conditions, the signal, which causes In the currently used 45-45 stereo record cutting The tonearm therefore must have sufficient effective On the other hand, for the mid to high frequencies, To summarise, the These conditions are almost impossible to achieve To illustrate how the system works in practice,

Cartridge behaviour with two different two different In these figures line A refers to the displacement However, the DV507 shows a much better tracking

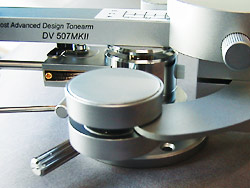

A non-contact, electro-magnetic damping mechanism

In this system, a curved rod attached to the As already demonstrated in our DV505 and

The tracking

High precision, stainless steel bearings are

Most tonearms have some frequency response

A larger arm lift has been To adjust the VTA (Vertical Tracking Angle of The anti-skating force is set using a dial indicator.

|

1 in stock

Description

The Long-Awaited Debut of the DV507MKII

The new MKII version of the Dynavector DV 507 tonearm

has made its long-awaited debut, building on the strengths of the

original DV 507 which has enjoyed the highest reputation among

audiophiles world-wide since its appearance in 1984.

As it is a bi-axis inertia controlled tonearm the

DV 507, no matter the type of cartridge can trace the music signal

grooves cut in the recording with extreme accuracy. The DV 507

also provides superb trackability on warped recordings. Resolution

and musical detailing are quite remarkable.

![]()

| 1 | Advantages of Bi-Axis Inertia Controlled Dynamic Balance Type Tonearm |

A tone arm is required to operate

in two important ways so as to ensure that the cartridge can

reproduce faithfully the signal from the record groove.

First, there is the need to support the cartridge

so that the transfer of the cantilever motion accurately mirrors

the audio signal.

Secondly, it must maintain an excellent tracking

ability for warped records since few records are perfectly flat.

These requirements can conflict with each other.

However, the bi-axis tonearm provides an effective solution to

the problem.

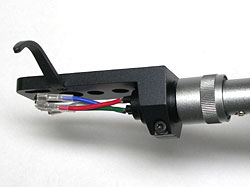

| 2 | Main Features |

-Electro Magnetic Damping System for accurate tracking

|

To make the DV 507 MKII compatible with a wide variety of The DV507MKII has important sonic improvements as well as being

"Bi-axis inertia separation" may The DV507 bi-axis tone arm has a large inertia It is well known that a cartridge generates In these conditions, the signal, which causes In the currently used 45-45 stereo record cutting The tonearm therefore must have sufficient effective On the other hand, for the mid to high frequencies, To summarise, the These conditions are almost impossible to achieve To illustrate how the system works in practice,

Cartridge behaviour with two different two different In these figures line A refers to the displacement However, the DV507 shows a much better tracking

A non-contact, electro-magnetic damping mechanism

In this system, a curved rod attached to the As already demonstrated in our DV505 and

The tracking

High precision, stainless steel bearings are

Most tonearms have some frequency response

A larger arm lift has been To adjust the VTA (Vertical Tracking Angle of The anti-skating force is set using a dial indicator.

|

Reviews

There are no reviews yet.